When it comes to industrial automation, the Powerflex 525 is a game-changer. This compact drive has become a go-to solution for controlling motor speeds and optimizing energy consumption. Whether you're a tech-savvy engineer or just starting out in the world of variable frequency drives (VFDs), understanding the Powerflex 525 parameters list can save you a ton of headaches. So, buckle up because we’re diving deep into the nitty-gritty details of this powerful little machine.

Imagine this: you’ve just installed your shiny new Powerflex 525, but now you’re scratching your head trying to figure out what all those parameters mean. Don’t worry, you’re not alone. The parameters list might seem overwhelming at first, but once you break it down, it’s like solving a puzzle—one piece at a time. And hey, who doesn’t love a good challenge?

Before we dive into the deep end, let’s set the stage. The Powerflex 525 isn’t just any drive; it’s designed to deliver top-notch performance with minimal fuss. From its intuitive setup to its robust features, this drive is built to handle a wide range of applications. But to unlock its full potential, you need to know the ins and outs of its parameter settings. That’s where this guide comes in.

Read also:Aaliya Yasin Rising Star In The Spotlight

Table of Contents

- Overview of Powerflex 525

- Understanding Powerflex 525 Parameters

- Step-by-Step Setup Guide

- Common Parameters Explained

- Optimizing Parameters for Efficiency

- Troubleshooting Common Issues

- Applications of Powerflex 525

- Maintenance Tips

- Upgrading Your Drive

- Conclusion

Overview of Powerflex 525

Let’s talk about the star of the show—the Powerflex 525. This drive is like the Swiss Army knife of industrial automation. Compact, versatile, and packed with features, it’s no wonder so many industries rely on it. Whether you’re working in manufacturing, HVAC, or even water treatment, the Powerflex 525 has got your back.

One of the coolest things about this drive is its user-friendly interface. Gone are the days of fumbling through complex menus and cryptic codes. With the Powerflex 525, setup is a breeze, thanks to its intuitive parameter structure. But here’s the thing—it’s still super powerful, capable of handling everything from simple motor control to advanced automation tasks.

Why Choose Powerflex 525?

There are plenty of VFDs out there, but the Powerflex 525 stands out for a few key reasons. First off, its energy efficiency is unmatched. If you’re looking to cut costs and reduce your carbon footprint, this drive is a no-brainer. Plus, its compact design makes it perfect for installations where space is limited.

Another big selling point? Reliability. This drive is built to last, with robust components that can withstand even the toughest environments. And let’s not forget about its scalability. Need to expand your system? No problem. The Powerflex 525 can grow with your business, ensuring you’re always prepared for the future.

Understanding Powerflex 525 Parameters

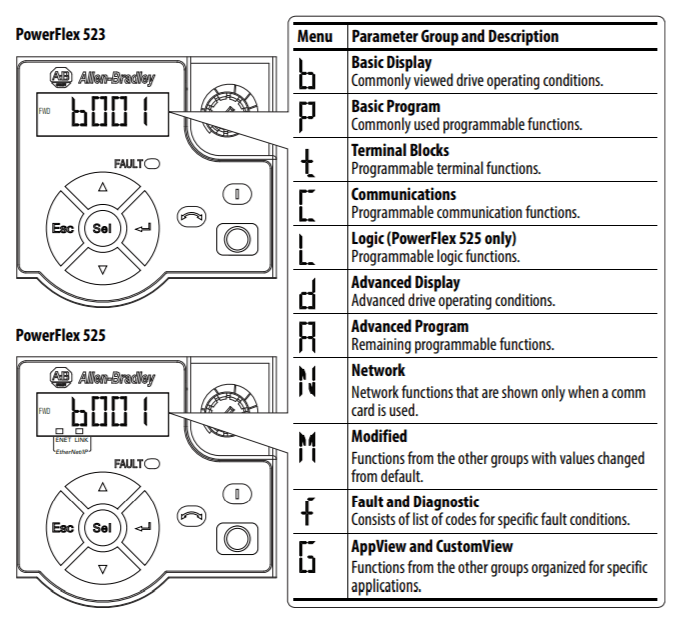

Alright, let’s get down to business. The Powerflex 525 parameters list is essentially the brain of the drive. These settings control everything from motor speed to fault detection. Think of them as the instructions that tell the drive how to behave in different situations.

Now, I know what you’re thinking—“How do I even start making sense of all these parameters?” Don’t worry, we’ve got you covered. Let’s break it down into manageable chunks so you can tackle each one with confidence.

Read also:Francesca Farago Onlyfans Leak What You Need To Know About The Controversy

Key Parameter Categories

- Motor Control Parameters: These are the bread and butter of the drive. They control how the motor operates, including speed, torque, and acceleration.

- Fault Parameters: These settings determine how the drive handles errors or faults. Think of them as the drive’s safety net, ensuring everything runs smoothly.

- Communication Parameters: If you’re integrating the Powerflex 525 into a larger system, these parameters are crucial. They allow the drive to communicate with other devices using protocols like Modbus or Ethernet/IP.

Step-by-Step Setup Guide

Setting up the Powerflex 525 doesn’t have to be a headache. With the right approach, you can have your drive up and running in no time. Here’s a quick step-by-step guide to help you along the way.

First things first, make sure you have all the necessary tools and documentation. You’ll need the drive itself, a computer with the Powerflex software installed, and of course, the parameters list. Now, let’s dive into the setup process.

Step 1: Initial Configuration

Begin by entering the basic motor data. This includes things like motor nameplate information, voltage, and current ratings. Don’t skip this step—it’s crucial for ensuring the drive operates within safe limits.

Step 2: Fine-Tuning Parameters

Once the basics are set, it’s time to dive into the more advanced parameters. This is where you can really customize the drive to suit your specific application. Whether you’re tweaking speed settings or adjusting fault thresholds, this step is all about optimization.

Common Parameters Explained

Let’s take a closer look at some of the most common Powerflex 525 parameters. Understanding these will give you a solid foundation for configuring your drive.

Parameter P1-01: Motor Speed

This parameter controls the maximum speed of the motor. It’s important to set this correctly to avoid over-speeding and potential damage to the motor.

Parameter P2-05: Acceleration Time

Here’s where you can adjust how quickly the motor ramps up to full speed. A longer acceleration time can help reduce mechanical stress, especially in heavy-duty applications.

Parameter P3-10: Fault Reset

This parameter determines how the drive responds when a fault occurs. You can set it to automatically reset after a certain period or require manual intervention, depending on your preference.

Optimizing Parameters for Efficiency

Now that you know the basics, it’s time to take things to the next level. Optimizing your Powerflex 525 parameters can lead to significant improvements in energy efficiency and overall performance.

One of the best ways to do this is by fine-tuning the motor control parameters. By adjusting settings like torque control and speed regulation, you can ensure the motor operates at peak efficiency. And let’s not forget about monitoring energy consumption. Keeping an eye on this metric can help you identify areas for improvement and make data-driven decisions.

Troubleshooting Common Issues

Even the best-laid plans can go awry sometimes. If you encounter issues with your Powerflex 525, don’t panic. Here are some common problems and how to fix them.

Problem: Drive Won’t Start

First, check the power supply. Make sure everything is connected properly and there are no loose wires. If that checks out, take a look at the fault parameters to see if there’s an underlying issue.

Problem: Motor Overheating

This could be due to several factors, including incorrect motor data or excessive load. Double-check your parameter settings and ensure the motor isn’t being pushed beyond its limits.

Applications of Powerflex 525

The Powerflex 525 is incredibly versatile, making it suitable for a wide range of applications. Here are just a few examples:

- Manufacturing: Use the drive to control conveyor belts, robotic arms, and other machinery.

- Water Treatment: Optimize pump performance and reduce energy consumption in water treatment plants.

- Heating, Ventilation, and Air Conditioning (HVAC): Improve airflow control and energy efficiency in HVAC systems.

Maintenance Tips

Regular maintenance is key to keeping your Powerflex 525 in top condition. Here are a few tips to help you stay on top of things:

- Inspect the drive periodically for signs of wear and tear.

- Keep the drive clean and free of dust, especially in harsh environments.

- Update firmware regularly to ensure you have the latest features and bug fixes.

Upgrading Your Drive

As your business grows, so too may your requirements for the Powerflex 525. Upgrading your drive can provide additional features and capabilities, helping you stay ahead of the curve.

Consider upgrading to newer models in the Powerflex series, which offer enhanced performance and connectivity options. Plus, with backward compatibility, you can often retain your existing parameter settings, making the transition smoother.

Conclusion

There you have it—the ultimate guide to the Powerflex 525 parameters list. Whether you’re a seasoned pro or just starting out, understanding these parameters is key to unlocking the full potential of your drive. By following the tips and tricks outlined in this article, you’ll be well on your way to mastering the Powerflex 525.

So, what are you waiting for? Dive in, experiment, and see just how much this drive can do for you. And don’t forget to share your experiences in the comments below—we’d love to hear from you!